Mechanical Engineering Department was started in the year 2004. Department is committed to well-being and all round development of its students.

Our faculties have extensive experience in industry, research as well as teaching. Our strength is a reflection of their skills. The department is recognized Research Center from VTU, more than 16 faculties are pursuing their PhD in the Department. The Department has received the grants upto 25 Lakhs from various agencies.

Mechanical Engineering changes under the influence of advanced computational tools, improved simulation analysis and entirely different manufacturing protocols. This has opened up new vistas of research in the department, such as Fracture Mechanics, Rapid Prototyping, Computational Heat Transfer, Solar Energy, Advanced Materials, Supply Chain Management, Advanced Manufacturing Processes, CAD/CAM/CIM, Robotics and Mechatronics. To work as a professional or as an entrepreneur by applying mechanical engineering principles and management practices.

The students of Mechanical Engineering carry out their Internships, Projects and Industrial Visits in well-known Industries. Also the students participated at National Level project Exhibitions and have presented numerous papers in conferences. As an annual event the Department conducts National Level Project Exhibition.

The Department takes pride in achievements of its alumni, who have shined in various walks of life.

Vision

Through the excellence of its people, the department of Mech. Engg. Will be recognized as a leader of its discipline in a manner exemplifies the land-grant tradition of learning, discovery and engagement.

Mission

Mechanical Department aims to provide quality education with a strong foundation in fundamental principles of Engineering, blended with professional and ethical responsibilities for the betterment of the society as a whole.

Course Outcomes:

Faculties frame the Course outcome by using the four components: Action, Knowledge, Condition, benchmark and shall focus on what the student should know and realistically be able to do by the end of the course.

Choose the Action verb required for learning based on the level, this measures the student ability in demonstrating the concept which is required (Apply, Analyze, . . . .).

The Knowledge and its level required to reach/achieve the concept, some of the concepts required are specific to the domain knowledge.

what are the conditions on which the above knowledge specified is achieved / or the conditions under which the operations happen to achieve the above said knowledge.

To characterize the acceptability levels of performing the action. Bench mark methods are specified for the Optional element.

Programme Specific Outcomes:

Department of Mechanical Engineering:

Graduates will have ability to:

Designation : Professor and Principal

Specialization: Manufacturing Science & Engg.

Qualification : M.Tech, Ph.D

Experience : 25 Years

E-mail: principal@skit.org.in

Profile Details Click

Here

Designation : Associate Professor and HoD

Specialization: Mechanical Engineering

Qualification : M.Tech, Ph.D

Experience : 13 Years

E-mail: sachidanandakbmech@skit.org.in

Profile Details Click

Here

Designation : Professor

Specialization: Machine Design

Qualification : M.Tech, (Ph.D)

Experience : 33 Years

E-mail: mechhod@skit.org.in

Profile Details Click

Here

Designation : Professor

Specialization: Thermal Power Engg.

Qualification : M.Tech, Ph.D

Experience : 18 Years

E-mail: krishnegowdamech@skit.org.in

Profile Details Click Here

Designation : Assistant Professor

Specialization: Production Engg.

Qualification : M.Tech, (Ph.D)

Experience : 13 Years

E-mail: chandraiahmech@skit.org.in

Profile Details Click

Here

Designation : Assistant Professor

Specialization: Composite Materials

Qualification : M.Tech, (Ph.D)

Experience : 13 Years

E-mail: mohankumarmech@skit.org.in

Profile Details Click Here

Designation : Assistant Professor

Specialization: Computer Integrated Manufacturing

Qualification : M.Tech, (Ph.D)

Experience : 12.5 Years

E-mail: pramodmech@skit.org.in

Profile Details Click

Here

Designation : Assistant Professor

Specialization: Tool Engineering

Qualification : M.Tech, (Ph.D)

Experience : 11.5 Years

E-mail: dineshmech@skit.org.in

Profile Details Click

Here

Designation : Assistant Professor

Specialization: Thermal Engineering

Qualification : M.Tech

Experience : 8.6 Years

E-mail: rajeshmech@skit.org.in

Profile Details Click

Here

Designation : Assistant Professor

Specialization: Thermal Power Engg

Qualification : M.Tech

Experience : 6 Years

E-mail: appesemech@skit.org.in

Profile Details Click

Here

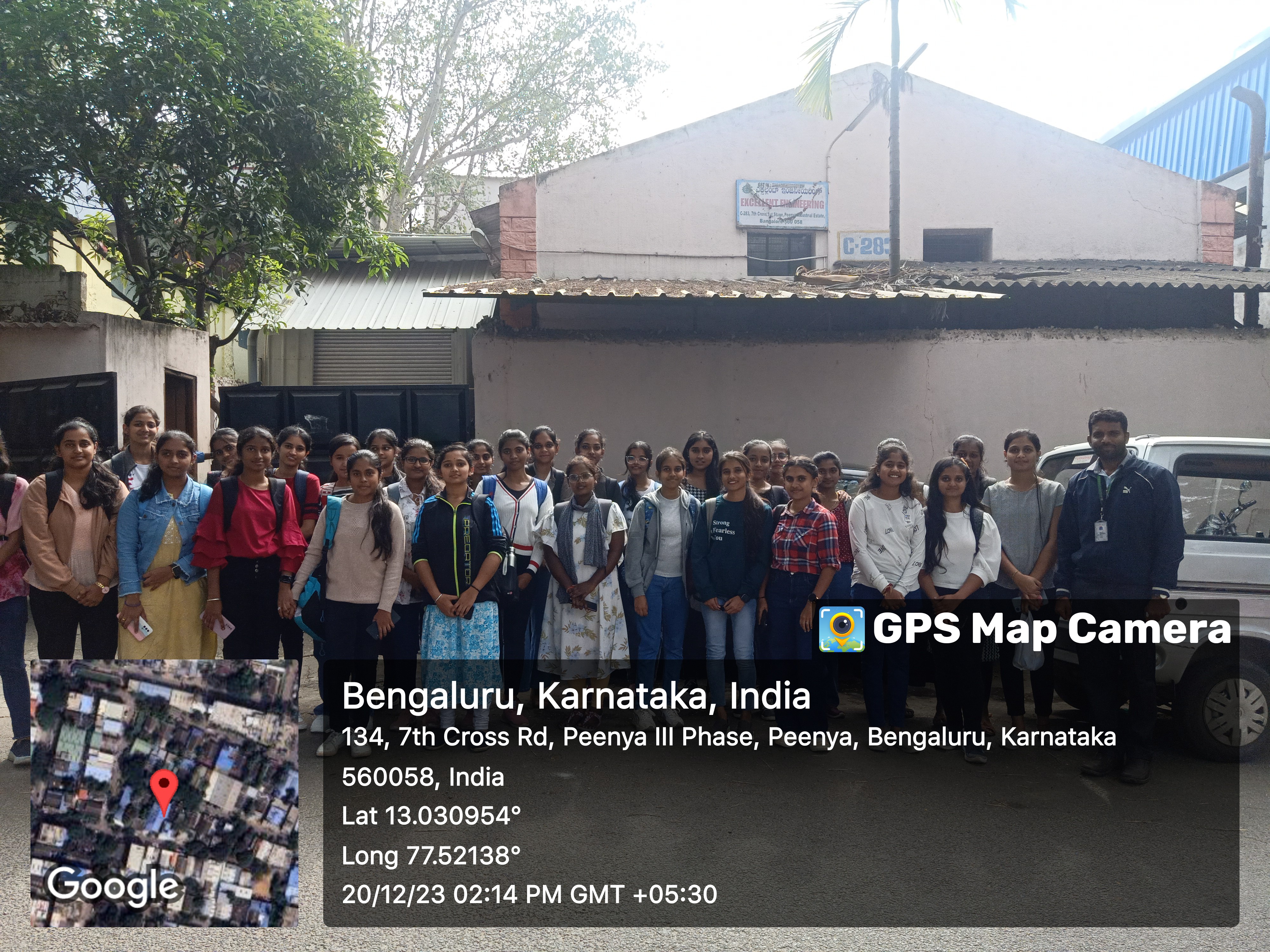

Industrial Visit for 1 st Semester Mechanical Engg. and Civil Engg. Students.

Mr. Ravish

To provide students an insight regarding working of CNC Lathe &

Milling Machines. The industrial visit to observe CNC Lathe and Milling machines serves

as a crucial link between theoretical knowledge and practical application. This

practical exposure reinforces their understanding of CNC technology. Witnessing

the actual operations of CNC Lathe and Milling machines helps students

comprehend how commands and programs are translated into physical movements

and machining processes.

Mr. Rajesh S C and Mr. A R Mohan Kumar

Department of Mechanical Engineering is VTU recognized Research and Development Center.

The department is funded from VGST under which different equipments like Computerized UTM, Fatigue Test Rig, Digital microscope and Digital Vickers Hardness Testing Machine are procured. More than 10 faculties of the department are pursuing PhD.

This lab helps the students to acquire knowledge of CAD software and its features. Students learn the theory of projection, make drawings using orthographic projections and sectional views and to familiarize the students with ISO standards. Also make them understand and interpret drawings of machine components so as to prepare assembly drawings both manually and using CAD packages like solid edge and AutoCAD

This lab helps the students to acquire knowledge about material by conducting test like destructive and nondestructive testing. On ferrous and nonferrous materials. In destructive testing tension, compression, shear, impact, hardness, bending, fatigue, creep, torsion and wear test are performed. In nondestructive testing magnetic particle and chemical spray testing is done. Also microstructure analysis for different materials is observed. Students and faculty also involve in preparing the specimens for testing and research is carryout in this lab. VGST has sponsored for the upgradation of the lab digital UTM, Digital fatigue, Digital Vickers hardness, digital metallurgical microscope and polishing machine are procured under this grants.

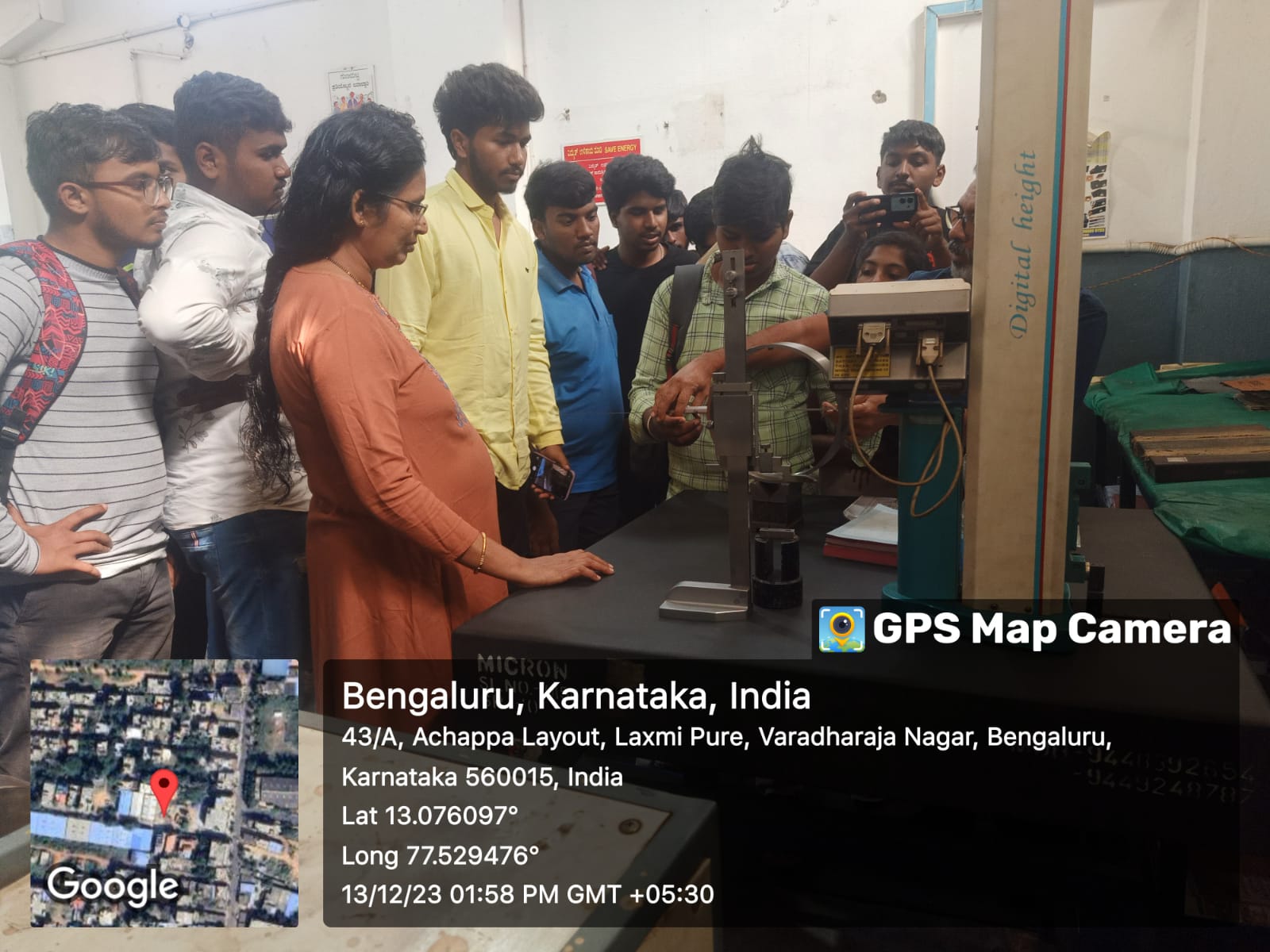

In this lab students are able to understand different measuring instruments to measure the qualitative and quantitative characteristics of different Mechanical Measuring equipments. To express the significance of measurement systems such as errors, transducers, intermediate modifying errors and correction factors of various measuring devices, by using different measuring tools such as Sine Bar, Sine Center, Bevel Protractor, Tool Maker Microscope, Gear Tooth Micrometer, Optical Flats, Linear variable differential transformer, dynamometer and profile projector experiments are conducted. All the above instruments are calibrated with the standards.

The students will be trained to operate and use different machines like Lathe, Milling machine, Grinding machine and Shaping machine. In each and every machine students are made to manufacture three different models individually. The students will be exposed to operate the machines for manufacturing any complicated component.

Students are taught to conduct experiments on two stroke, four stroke, petrol and diesel engines.

For all the engines the performance characteristics is evaluated by both theoretically and experimentally. For all the experiments the students are made to determine the engine efficiency at different loading conditions.

Before performing the experimentation the fuel is prepared and its characteristics are determined like flash point, fire point, viscosity, specific gravity using calorimeters.

The lab is equipped with latest computerized test rig.

This lab is run in conjunction with the theory course Fluid Mechanics. It is an introductory course where flow behavior and fluid forces are studied. The goals of the experiments include determination of forces generated when fluid flow takes place over a solid object.

Applications of the control volume approach, demonstration of the momentum and energy equations, viscosity measurement and engineering correlations are studied. Intricate flow phenomena such as separations and transition to turbulence are demonstrated. Experimental setups such as flow through a tube, flow over a flat plate and viscometer are made available to the students.

This lab trains the students to perform the coefficient of discharge using flow measuring devices like Orifice and Venturimeters. Test basic performance parameters of hydraulic turbines and pumps. Determine the energy flow pattern through the hydraulic turbines and pumps.

The lab provides the advanced knowledge in understanding the concepts of Mechanical Vibrations & Dynamics of Machine. The students perform experiments on advanced Gyroscope, Journal bearing, Polariscope, balancing of rotating masses, Whirling of shafts, Vibration test rig and strain rosettes. The students will learn to control vibrations in different working conditions.

Heat Transfer laboratory provides fundamental and industrial knowledge about modes of heat transfer like conduction, convection and radiation and their applications. Also students will perform experimentation on refrigeration and air conditioning cycles to determine the thermal conductivity of metal rod, convection and correlate with theoretical convective heat transfer coefficient for free and forced values. Also they will calculate temperature distribution of steady and transient heat conduction effectiveness of fin wall.

Modeling and analysis lab is associated with FEM theory subject. The fully Licensed version of ANSYS software is used in the laboratory which helps for research and consultancy projects. The student learns to use the software for preprocessing, processing and post processing operation on 2D, 3D, static, dynamic, heat transfer and flow problems. The results are evaluated by both mathematical and computational methods for bar, beam, structural, plate and for combination of materials.

| ACADEMIC YEAR: 2024-25(Odd Sem), SCHEME: 2022, SEM: III, SEC: A | ||||||

|---|---|---|---|---|---|---|

| Sl.No | COURSE CODE | COURSE NAME | THEORY / PRACTICAL | FACULTY IN-CHARGE | COURSE WEBSITE LINK | APPROVED BY HOD YES/NO |

| 1 | BME301 | Mechanics of Materials | THEORY | Mr. Chandraiah MT | https://shorturl.at/VUM1m | YES |

| 2 | BME302 | Manufacturing Process | THEORY | Mr. Dinesh P | https://sites.google.com/skit.org.in/mp24-25/about-the-faculty | YES |

| 3 | BME303 | Material Science and Engineering | THEORY | Mr. Pramod SN | https://shorturl.at/4tv02 | YES |

| 4 | BME304 | Basic Thermodynamics | THEORY | Dr. Krishnegowda B M | https://tinyurl.com/352psn56 | YES |

| 5 | BMEL305 | Introduction to Modelling and Design for Manufacturing | PRACTICAL | Dr. Sachidananda K B | https://sites.google.com/skit.org.in/kbs-website?usp=sharing | YES |

| 6 | BME306A | Electric and Hybrid Vehicle Technology | THEORY | Mr. Appese S D | https://sites.google.com/skit.org.in/asdevhy/about-the-faculty- | YES |

| 7 | BSCK307 | Social Connect and Responsibility | PRACTICAL | Mr. Appese SD | https://sites.google.com/skit.org.in/scr307/home | YES |

| 8 | BME358C | Spreadsheet for Engineers | PRACTICAL | Mr. Chandraiah MT | https://shorturl.at/emPry | YES |

| ACADEMIC YEAR: 2024-25(Odd Sem), SCHEME: 2022, SEM: V, SEC: A | ||||||

|---|---|---|---|---|---|---|

| Sl.No | COURSE CODE | COURSE NAME | THEORY / PRACTICAL | FACULTY IN-CHARGE | COURSE WEBSITE LINK | APPROVED BY HOD YES/NO |

| 1 | BME501 | Industrial Management & Entrepreneurship | THEORY | Mr. Dinesh P | https://sites.google.com/skit.org.in/m-and-e-24-25/lecture-notes | YES |

| 2 | BME502 | Turbo machines | THEORY | Mr. Rajesh S C | https://sites.google.com/skit.org.in/vseintm/lab-manual | YES |

| 3 | BME503 | Theory of Machines | THEORY | Prof. Sreenivasan A | http://surl.li/wlvweo | YES |

| 4 | BME504L | CNC Programming and 3-D Printing lab | PRACTICAL | Mr. AR Mohan Kumar | https://sites.google.com/skit.org.in/cnclab/about-the-course | YES |

| 5 | BME515D | Energy Engineering | THEORY | Mr. Appese S D | https://sites.google.com/skit.org.in/bme515d/about-the-faculty | YES |

| 6 | BRMK557 | Research Methodology and IPR | THEORY | Dr. Satish K | https://sites.google.com/d/1RgbBw-c6uEFb3hG7cPmxUEE3jsFVVs4cP/edit | YES |

| ACADEMIC YEAR: 2024-25(Odd Sem), SCHEME: 2021, SEM: VII, SEC: A | ||||||

|---|---|---|---|---|---|---|

| Sl.No | COURSE CODE | COURSE NAME | THEORY / PRACTICAL | FACULTY IN-CHARGE | COURSE WEBSITE LINK | APPROVED BY HOD YES/NO |

| 1 | 21ME71 | Automation and Robotics | THEORY | Mr. Rajesh S C | https://sites.google.com/skit.org.in/vii-sem-ar/vtu-qsn-papers | YES |

| 2 | 21ME72 | Control Engg. | THEORY | Dr. Krishnegowda B M | https://sites.google.com/skit.org.in/7thsem/home- | YES |

| 3 | 21ME731 | Additive Manufacturing | THEORY | Mr. Pramod S N | https://shorturl.at/F49cH | YES |

| 4 | 21ME742 | Theory and Design of IC Engines | THEORY | Mr. Appese S D | https://sites.google.com/skit.org.in/asd-tdice/about-the-faculty- | YES |

| 5 | 21CS751 | Programming in Python | THEORY | Mrs. Roopa B | https://sites.google.com/view/progra mming-in-python1/about-the-course | YES |

| ACADEMIC YEAR: 2022-23(Even Sem) | ||||||

|---|---|---|---|---|---|---|

| Sl.No | COURSE CODE | COURSE NAME | THEORY / PRACTICAL | FACULTY IN-CHARGE | COURSE WEBSITE LINK | APPROVED BY HOD YES/NO |

| 1. | 21ME42 | Machining Science and Jigs & Fixtures | THEORY | Mr. Dinesh P | https://sites.google.com/skit.org.in/msjf/about-the-faculty | YES |

| 2. | 21ME43 | Fluid Mechanics | THEORY | Mr. Rajesh S C | http://tinyurl.com/msvua8hv | YES |

| 3. | 21ME44 | Mechanics of Materials | THEORY | Mr. Chandraiah M T | https://sites.google.com/skit.org.in/mechanics-of-materials-21me44/best-practices | YES |

| 4. | 21MEL46 | Mechanical Measurements and Metrology | PRACTICAL | Mr. Dinesh P | http://surl.li/hesfy | YES |

| ACADEMIC YEAR: 2022-23(Even Sem) | ||||||

|---|---|---|---|---|---|---|

| Sl.No | COURSE CODE | COURSE NAME | THEORY / PRACTICAL | FACULTY IN-CHARGE | COURSE WEBSITE LINK | APPROVED BY HOD YES/NO |

| 1. | 18ME61 | Finite Element Methods | THEORY | Dr. Krishnegowda B M | https://tinyurl.com/md4k3mwu | YES |

| 2. | 18ME62 | Design of Machine Elements II | THEORY | Prof. Sreenivasan A | http://tinyurl.com/3dpr5tss | YES |

| 3. | 18ME63 | Heat Transfer | THEORY | Dr. Krishnegowda B M | https://tinyurl.com/4ez3f6zb | YES |

| 4. | 18ME641 | Non-Traditional Machining | THEORY | Mr. Dinesh P | http://tinyurl.com/mrejuvv4 | YES |

| 5. | 18CS652 | Introduction to Data Structures and Algorithm | THEORY | Mrs. Ragini Krishna | https://sites.google.com/skit.org.in/6th-sem-ds-alg/home | YES |

| 6. | 18ME651 | Non-Conventional Energy Sources | THEORY | Mr. Appese S D/Mr. Rajesh S C/Mr. Pramod S N | https://sites.google.com/skit.org.in/vi-sem-cse-a-sec-nces/about-the-course/question-bank | YES |

| 7. | 18MEL66 | Computer Aided Modelling and Analysis Lab | PRACTICAL | Mr. Pramod S N | https://sites.google.com/skit.org.in/cam-lab/about-the-faculty | YES |

| 8. | 18MEL67 | Heat Transfer Lab | PRACTICAL | Mr. Appese S D | https://sites.google.com/skit.org.in/energy-/ht-lab | YES |

| ACADEMIC YEAR: 2022-23(Even Sem) | ||||||

|---|---|---|---|---|---|---|

| Sl.No | COURSE CODE | COURSE NAME | THEORY / PRACTICAL | FACULTY IN-CHARGE | COURSE WEBSITE LINK | APPROVED BY HOD YES/NO |

| 1. | 18ME81 | Energy Engineering | THEORY | Mr. Pramod S N | https://sites.google.com/skit.org.in/18me81-energy-engg/home | YES |

| 2. | 18ME824 | Automobile Engineering | THEORY | Mr. Appese S D | https://sites.google.com/skit.org.in/appu/about-the-faculty | YES |

| ACADEMIC YEAR: 2023-24(Odd Sem) | ||||||

|---|---|---|---|---|---|---|

| Sl.No | COURSE CODE | COURSE NAME | THEORY / PRACTICAL | FACULTY IN-CHARGE | COURSE WEBSITE LINK | APPROVED BY HOD YES/NO |

| 1. | BME301 | Mechanics of Materials | THEORY | MR. CHANDRAIAH M T | https://shorturl.at/dxyT9 | YES |

| 2. | BME303 | Material Science and Engineering | THEORY | MR. PRAMOD S N | HTTPS://TINYURL.COM/MR3FPAYV | YES |

| 3. | BME304 | Basic Thermodynamics | THEORY | MR. RAJESH S C | HTTPS://TINYURL.COM/BDD6PBXS | YES |

| 4. | BMEL305 | Introduction to Modelling and Design for Manufacturing | PRACTICAL | MR. A R MOHAN KUMAR | HTTPS://TINYURL.COM/3N6MFMJX | YES |

| 5. | BME306A | Electric and Hybrid Vehicle Technology | THEORY | MR. APPESE S D | https://sites.google.com/skit.org.in/asdevhy/about-the-faculty | YES |

| ACADEMIC YEAR: 2023-24(Odd Sem) | ||||||

|---|---|---|---|---|---|---|

| Sl.No | COURSE CODE | COURSE NAME | THEORY / PRACTICAL | FACULTY IN-CHARGE | COURSE WEBSITE LINK | APPROVED BY HOD YES/NO |

| 1. | 21ME51 | Theory of Machines | THEORY | MR. CHANDRAIAH M T | https://shorturl.at/fCFQW | YES |

| 2. | 21ME52 | Thermo-fluids Engineering | THEORY | MR. Rajesh S C | https://sites.google.com/skit.org.in/vsemme/home | YES |

| 3. | 21ME53 | Finite Element Analysis | THEORY | Dr.Krishne Gowda B M | https://tinyurl.com/2s4j6rfn | YES |

| 4. | 21ME54 | Modern Mobility and Automotive Mechanics | PRACTICAL | MR. Appse S D | https://sites.google.com/skit.org.in/appes/about-the-faculty | YES |

| 5. | 21MEL55 | Design lab | Practical | Mr. Dinesh P | http://tinyurl.com/3jehh857 | YES |

| ACADEMIC YEAR: 2023-24(Odd Sem) | ||||||

|---|---|---|---|---|---|---|

| Sl.No | COURSE CODE | COURSE NAME | THEORY / PRACTICAL | FACULTY IN-CHARGE | COURSE WEBSITE LINK | APPROVED BY HOD YES/NO |

| 1. | 18ME71 | CONTROL ENGG. | THEORY | DR. KRISHNEGOWDA B M | https://tinyurl.com/txa7wtt7 | YES |

| 2. | 18ME72 | CAD & M | THEORY | PRAMOD S N | HTTPS://TINYURL.COM/4Z4NDU6N | YES |

| 3. | 18ME734 | TQM | THEORY | DINESH P | https://tinyurl.com/bddrpber | YES |

| 4. | 18ME741 | ADDITIVE MANUFACTURING | THEORY | PRAMOD S N | https://tinyurl.com/69xj7c3m | YES |

| 5. | 18ME751 | ENERGY & ENVIRONMENT | THEORY (OE) | MR. APPESE S D MR. RAJESH S C DR. KRISHNEGOWDA B M | https://tinyurl.com/4xk3unec | YES |

| 6. | 18MEL76 | CIM LAB | PRACTICAL | PRAMOD S N | https://tinyurl.com/56b97dc3 | YES |

| 7. | 18ME77 | DESIGN LAB | Practical | DINESH P | http://tinyurl.com/3jehh857 | YES |

| Student Placed in 2023 | ||||||

|---|---|---|---|---|---|---|

| Sl.No | Candidate Name | Company Name | Designation | On Campus / Off Campus | ||

| 1. | THANUJ KUMAR S | thanujkumar.mech@skit.org.in | Intelipaat | BDA | On Campus | |

| 2. | THANUJ KUMAR S | thanujkumar.mech@skit.org.in | Skillvertex | BDA | On Campus | |

| 3. | MUHAMMED ANEESH KP | mdaneesh@skit.org.in | Academor | Academic Counsellor | On Campus | |

| Student Placed in 2022 | ||||||

|---|---|---|---|---|---|---|

| Sl.No | USN | Candidate Name | Branch | Company Name | Designation | Package |

| 1. | 1KT18ME018 | Sumanth Manjunath | ME | Capgemini Pentagon Space Pvt Ltd |

Analyst Assistant System Engineer Trainee |

4 LPA 3.6 LPA |

| 2. | 1KT18ME008 | Harshith Gowda K G | ME | Turing Minds Pentagon Space Pvt Ltd |

Data scientist Assistant System Engineer Trainee |

5 LPA 3.6 LPA |

| 3. | 1KT17ME027 | Rakesh K | ME | Mindtree | Engineer | 4 LPA |

| 4. | 1KT19ME410 | Tilak Gowda H K | ME | Palle Technologies | Software Testing Trainee | 3.0 LPA |

| 5. | 1KT18ME009 | Kirana Swamy S | ME | Q Spiders | Software Testing Trainee | 3.0 LPA |

| 6. | 1KT17ME034 | Vivek C H | ME | Q Spiders | Software Testing Trainee | 3.0 LPA |

| Student Placed in 2021 | ||||

|---|---|---|---|---|

| Sl.No | USN | Candidate Name | Branch | Company Name |

| 1. | 1KT18ME008 | Harshith Gowda K G | ME | Pentagon Space Pvt Ltd |

| 2. | 1KT18ME018 | Sumanth Manjunath | ME | Pentagon Space Pvt Ltd |

| 3. | 1KT19ME410 | Tilak Gowda H K | ME | Palle Technologies |

| Student Placed in 2020 | |||||

|---|---|---|---|---|---|

| Sl.No | Candidate Name | Branch | Company Name | Designation | Package |

| 1. | Girisha B V | ME | Byju's | Business Development - Trainee | 10 LPA |

| 2. | Pavan Kumar | ME | Balaji Panel Crafts | Quality Engineer | 3.6 LPA |

| 3. | Darshan H | ME | SKF India Pvt Ltd | Maintenance Engineer Trainee | 3.5 LPA |

| 4. | Darshan E C | ME | RNS Motors | Supervisor | 3.5 LPA |

| 5. | Prajwal Jgalore | ME | Tata Consultancy Services | Assistant System Engineer | 3.3 LPA |

| 6. | Chethan SN | ME | Prad 4X4 | Assistant Design Engineer | 3.6 LPA |

| 7. | Prakash | ME | Prerana Motors | Technician | 2.0 LPA |

| 8. | Likitha S N | ME | Prerana Motors | Technician | 2.0 LPA |

| Student Placed in 2019 | |||||

|---|---|---|---|---|---|

| Sl.No | Company Name | Designation | Package | Branch | Selected |

| 1. | X Works | Software testing | 2.5 LPA | ME | 4 |

| Student Placed in 2018 | |||||

|---|---|---|---|---|---|

| Sl.No | Candidate Name | Branch | Company Name | Designation | Package |

| 1. | ABHAY | MECH | GO SPEEDY GO | GRADUATE ENGINEER TRAINEE | 4.12 LAKHS |

| 2. | BHARATH YADAV | MECH | WESTLINE | TRAINEE MARINE ENGINEER | 1.5- 6 LAKHS |

| 3. | GAGAN SK | MECH | Q SPIDERS & J SPIDERS | TRAINEE | 2-6 LAKHS |

| 4. | MEHUL S | MECH | VEE TECHNOLOGIES | AR CALLER TRAINEE / MEDICAL CODER | 1.5 - 2 LAKHS |

| 5. | SACHIN | MECH | GO SPEEDY GO | GRADUATE ENGINEER TRAINEE | 4.12 LAKHS |

Date and Venue: 22th MARCH 2025, SKIT

Resource person: Prof Vishnu Namboodiri, HSE, NUCS, Hyderabad.

Event objective and outcomes:

This Webinar gives the technical roles to managerial leadership is one of the most significant challenges faced by professionals in the CRIP (Cybersecurity, Risk, and Information Protection) sector. This webinar aims to provide insights and guidance on how technical experts can successfully navigate this shift. This report outlines the proposal for a comprehensive seminar designed to equip professionals in the CRIP sector with the tools and knowledge necessary for a successful shift into leadership roles.

Event Co-Ordinator: Mr. Rajesh S C

Date and Venue: 19/03/2025. TVS Electronics, Pandithanahalli,

Hirehalli Industrial Area, Tumkur.

Event objective and outcomes:

This Industrial Visit gives an insight into the manufacturing and assembly processes involved in producing electronic products, components, or systems at TVS Electronics. To provide practical exposure for students to the industrial environment and develop a better understanding of the day-to-day operations in a manufacturing plant.

Event Co-Ordinator: Mr. Mohan Kumar A R

Date and Venue: 25-11-2024, T-309 Class Room

Event objective and outcomes:

From this event our students and audience came to know that Nourish to flourish “Pure Plant Power” i.e healthier food from vegetables and fruits. Today’s food markets are too focused on highly processed foods, rich in calories, which have led to an increase in obesity and diet-related diseases. At the end of this event, the student will be able to Communicate and connect to the surrounding. Create a responsible connection with the society. Involve in the community in general in which they work. Notice the needs and problems of the community and involve them in problem –solving. Develop competence required for group-living and sharing of responsibilities & gain skills in mobilizing community participation to acquire leadership qualities and democratic attitudes.

Event Co-Ordinator: Prof. Appese S D

Date and Venue: 6th November 2024 at 11:00 AM

Resource person: Mr. P. M. PRABHU, Program director, Avinya Networks,

Rajaji Nagar, Bengaluru

Event objective and outcomes:

This expert talk on “Industrial IOT Application in Manufacturing” aims at the manufacturing specifically, IIoT has the potential to provide quality control, sustainable and green practices, supply chain traceability and overall supply chain efficiency. This event outcome is one of the key benefits of using IoT is predictive maintenance, which involves ongoing monitoring of systems and processes to identify key indicators of problems before they result in downtime or system failure in manufacturing industries.

Event Co-Ordinator: Prof. Appese S D

Date and Venue: Saturday 27th July 2024, T-309 Classroom, SKIT.

Resource person: Mr. Vikas Kumar

Event objective and outcomes:

This event on Career Opportunities in Mechanical Industries aims at opening a industries dimension and a holistic perspective in industry & education collaboration in order to help our students to understand the complex realities and processes of today’s world and develop values, attitudes, knowledge and skills that will enable them to face the challenges of an interconnected world. This event outcome is like; Effective skill Development & Experiential Learning in networking.

Event Co-Ordinator: Prof. Appese S D

Date and Venue: 21/02/2024 SKIT Seminar Hall

Resource person: Mrs. Lakshmi Bai P G

Event objective and outcomes:

Engineers in leadership positions from each of the selected industrial segments participated in in-depth interviews and discussed about the expected engineering communication skills in industry. Outcome: In all industrial segments, oral communication, especially face-to-face update meetings, is very frequent and demands that engineers have the appropriate abilities to communicate in teams and in dyadic interactions.

Event Co-Ordinator: Prof. Sindhu K, Department of AI &ML

To provide students an insight regarding working of CNC Lathe & Milling Machines. The industrial visit to observe CNC Lathe and Milling machines serves as a crucial link between theoretical knowledge and practical application. This practical exposure reinforces their understanding of CNC technology. Witnessing the actual operations of CNC Lathe and Milling machines helps students comprehend how commands and programs are translated into physical movements and machining processes.

A four-stroke engine was disassembled, and all parts of the engine like engine head, piston, valves, connecting rod, camshafts, intake manifold, exhaust manifold, oil pump and carburetor etc. were shown to the students. This engine service provide a vibrant platform for students to learn the practical applications of engineering. The students know the awareness of modern-day technology and become well equipped to contribute their bit to the ever-evolving world of technology.

To provide students an insight to the different manufacturing domains within mechanical Engg. With modern inventions and its updation as per recent advancement on par with Industry 4.0. Students were exposed to latest technological advancement in manufacturing domain and also explored the various opportunities for internship, Industry visit and project work.

To provide students an insight to the different construction equipment manufacturer with modern inventions and its updation as per recent advancement on par with Industry 4.0. Students were exposed to latest technological advancement in construction equipment manufacturing domain and also explored the various opportunities for internship, Industry visit and project work.

To provide the skill development for the students on interfacing and working of CNC machine and CNC Turing. The students stands to gain the skill about actual interfacing of the written part programming on to the CNC machine and CNC turning machines which exposes to the practical constraints compaired to the theoretical knowledge.

To provide students an insight regarding working of CNC Lathe & Milling Machines. The industrial visit to observe CNC Lathe and Milling machines serves as a crucial link between theoretical knowledge and practical application. This practical exposure reinforces their understanding of CNC technology. Witnessing the actual operations of CNC Lathe and Milling machines helps students comprehend how commands and programs are translated into physical movements and machining processes.

Students were taken to the “Excellent Engineering Enterprises” as Industry Visit on 11/03/2022. It provided students with an opportunity to learn practically through interaction, working methods, and employment practices. The main aim of industrial visits is to provide exposure to students about practical working environments. They also provide students a good opportunity to gain full awareness about industrial practices.

The Dept. of Mechanical Engg. Organized “Art of Project Report Writing” for the

third-year

students of Mechanical Engineering. on 24/05/2023 from 2 to 3:30pm at B-113 class room.

The

objective is to provide platform for students to create awareness about the selection of

project during the academic year and to know the how to identify the problem in the

previous

project work.

Resource Person: Mr. Rajesh S C

It provides students with an opportunity to learn practically through interaction, working methods, and employment practices. The main aim of industrial visits is to provide exposure to students about practical working environments. They also provide students a good opportunity to gain full awareness about industrial practices. - Mr. Chandraiah M T

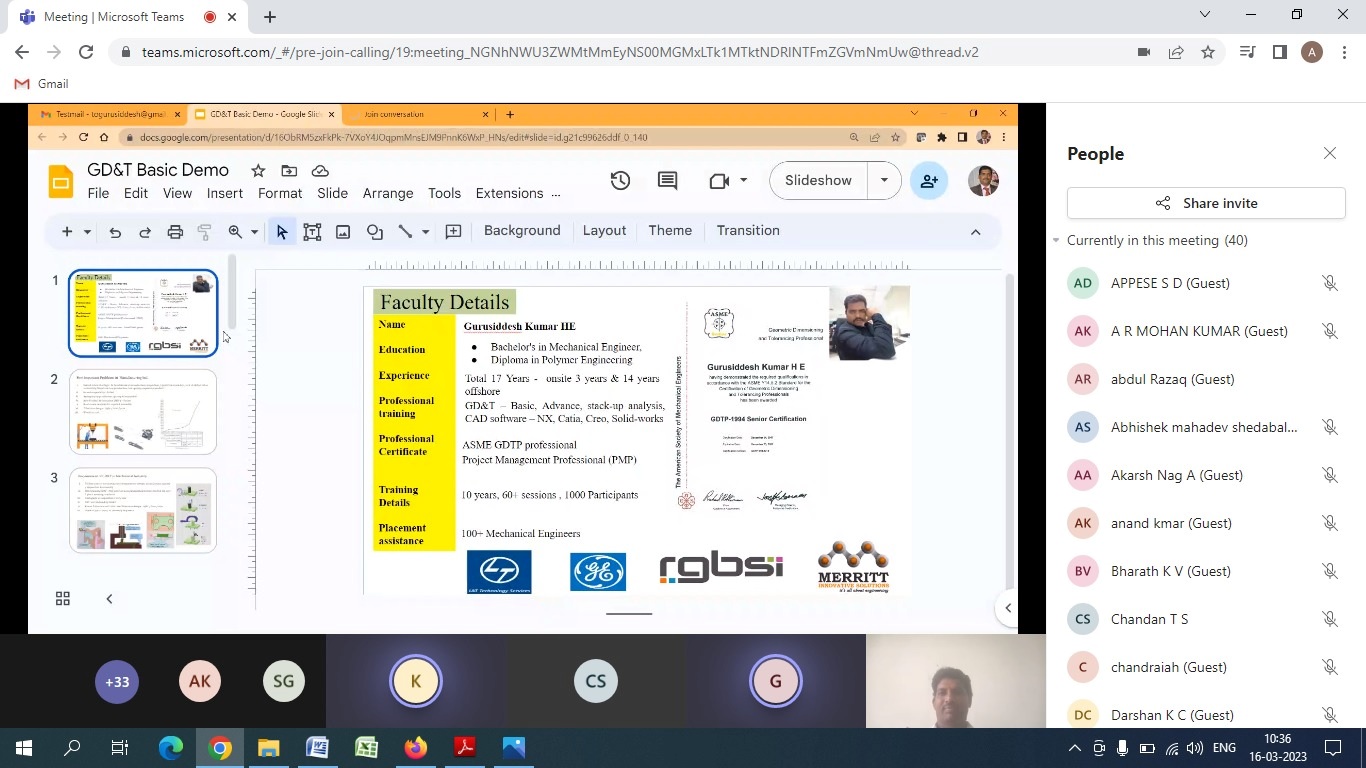

Mr. Guru Siddesh Kumar, Asst Manager, Terex Corporation To provide students an insight regarding GD&T and will be made aware that manufacturing any component the knowledge of Geometrical Dimensioning and Tolerancing is a must. GD&T is a precise language of engineering symbols that clearly communicate the design intent of the part. The result is an improvement in communication and part quality, The GD&T methodology is cur:rently used in Automotive, Heavy Equipment, Aviation and several other industries. Co-Ordinator: Mr. A R Mohan Kumar

A Webinar on “Adaption of CAD & CAE in Design Engineering” was organized on 13/07/2021.The Resource person was Piyush Hedaoo (Center of Excellence in Maritime and Shipbuilding Govt. of India), Mumbai. During this webinar, he motivated the participants to improve thinking skills and Mechanical Software’s skills like Solid works, Siemens NX, LMS Amesim, FEMAP, and PTC Creo.

An awareness program on “Career opportunities in Air Force” was organized on 23/02/2022 to get insight of career opportunities in Indian Airforce, the successful completion of the said induction drive and motivation lecture, students were exposed to virtual cockpit in Induction publicity vehicle and about entrance exams and various criteria to join Indian Air Force.

Department of Mechanical Engineering SKIT conducted quiz on "Thermal Engineering-2020" for all UG & PG students, Staffs of Mechanical, Automobile Engg. branches from 23rd May to 25th May. About 1250 participants from karnataka and outside Karnataka participated the quiz and were awarded with E-Certificates.

Department of Mechanical Engineering SKIT conducted quiz on "Production & Manufacturing" for the UG, PG students, Scholars, faculty from Mech. Engg, production Engg and Automobile Engg. About 1050 participants participated the quiz and were awarded with E-Certificates. The quiz was held on 26th May 2020.

Department of Mechanical Engineering conducted a quiz on "Design Engineering-2020" for the students and staffs. Students of UG & PG, Faculties from Mechanical, Automobile Engg. Streams attended the quiz. About 850 participants participated the quiz and were awarded with E-Certificates. The event was held on 27th May 2020.

Department of Mechanical Engineering in association with CADMAXX Bangalore arranged a webinar on "Awareness on Industrial application of CAD/CAM/CAE" for final year & pre final year students of SKIT. The students were educated about the opportunity of Mechanical Engineering graduates in the field of modeling, Analysis and Simulation sectors. About 80 students and staffs attended the webinar. Webinar was conducted on 2nd May 2020

Department of Mechanical Engineering had organized 5 days skill development program from 08.11.2019 – 12.11.2019 in association with cadd center Peenya, Bangalore. Students were exposed to various methods of NTD and hands on training was given on crack detection on the metal plates.

Department of Mechanical Engineering and Basic Sciences organized One day National Conference on “Recent Trends in Mechanical Engineering & Applied Science (RTME&AS 2018)” on 17th May, 2018. Chief Guest and Keynote Speaker, Mr. NaganaGouda, Director, National Training Center Solar Technology addressed the gathering and released the Conference Souvenir. Around 90 papers were presented and published in International Journal of Innovative Research in Science, Engineering and Technology IJIRSET with ISSN (online): 2319-8753 / ISSN (print): 2347-6710 in special issue.

2 days Skill Development Certification Program was conducted for 8th semester students on 10th and 11th march 2019 by the Department of Mechanical Engg in association with Indian tech keys where students were exposed to 3D printing technology, its software architecture also hands on experience on the same.

Students Achievement

| Academic Year - 2022-23 | ||||

|---|---|---|---|---|

| List of Toppers 2022-23 | ||||

| Sl.No. | USN | Name of the Student | Project Title | Details of Participation / Winning |

| 1. | 1KT20ME002 | Hemanth A S | “Enhancement in Mechanical Properties of Alumina Mixed with Epoxy Matrix Aluminium Substrate” | Anveshana-24 Project Exhibition won 2nd Prize |

| 2. | 1KT21ME400 | Abhishek K | “Enhancement in Mechanical Properties of Alumina Mixed with Epoxy Matrix Aluminium Substrate” | Anveshana-24 Project Exhibition won 2nd Prize |

| 3. | 1KT21ME401 | Ashish K S | “Enhancement in Mechanical Properties of Alumina Mixed with Epoxy Matrix Aluminium Substrate” | Anveshana-24 Project Exhibition won 2nd Prize |

| 4. | 1KT21ME402 | Kevin Steevan D’souza | “Enhancement in Mechanical Properties of Alumina Mixed with Epoxy Matrix Aluminium Substrate” | Anveshana-24 Project Exhibition won 2nd Prize |

| Academic Year - 2022-23 | ||||

|---|---|---|---|---|

| List of Toppers 2022-23 | ||||

| Sl.No. | USN | Name of the Student | Sem | Percentage (%) |

| 1. | 1KT19ME009 | THANUJ KUMAR S | VII | 80.63 |

| 2. | 1KT21ME405 | VISHWA P | V | 71 |

| 3. | 1KT21ME006 | SURYA GAYITHRI | III | 78.25 |

| 4. | 1KT19ME009 | THANUJ KUMAR S | VIII | 89 |

| 5. | 1KT20ME002 | HEMANTH A S | VI | 72.37 |

| Student Placed in 2021 | ||||

|---|---|---|---|---|

| Sl.No | Name of the student(s) | Details of Participation/ Winning | Place | |

| 1. | Mr. Vardhan Kulkarni | United Nations Development Program (UNDP) won 1lakh rupees to develop Start-up challenge event for Youth. | Project code- UNNATI | |

| 2. | Mr. Neelesh M V Mr. Puttaswamy Mr. Manjunath Gowda Mr. Dhanush V |

Anveshana- 2022, Project Exhibition Won 2nd Prize | SKIT | |

| 3. | Mr. Nagendra R Mr. Ajay G Naik Mr. Nagatilak Mr. Vardhan Kulkarni |

Anveshana- 2022, Project Exhibition Won 1st Prize | SKIT | |

Faculty Achievement

Attended: Workshop, Seminar, Conference, FDP

Organized: Workshop, Seminar, Conference, FDP

| Academic Year - 2024-25 (Even Sem) | ||||

|---|---|---|---|---|

| Toppers list: 4th sem (22 Scheme) | ||||

| Sl.No | Name | USN | Total marks | Percentage |

| 1 | RADHA D N | 1KT23ME009 | 591/800 | 73.88 |

| 2 | CHARAN M | 1KT24ME400 | 536/800 | 67 |

| Toppers list: 6th sem (22 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total marks | Percentage |

| 1 | SHARANABASAPPA B N | 1KT23ME401 | 621/800 | 77.62 |

| Toppers list: 8th sem (21 scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total marks | Percentage |

| 1 | SURYA GAYATHRI | 1KT21ME006 | 290/300 | 96.67 |

| 2 | SANJAY V T | 1KT21ME005 | 283/300 | 94.33 |

| 3 | BHARATH | 1KT22ME401 | 278/300 | 92.67 |

| 1 | SHREECHARAN A | 1KT22ME400 | 278/300 | 92.67 |

| Academic Year - 2024-25 (Odd Sem) | ||||

|---|---|---|---|---|

| Toppers list: 3rd sem (22 Scheme) | ||||

| Sl.No | Name | USN | Total marks | Percentage |

| 1 | CHARAN A | 1KT24ME400 | 563/800 | 70.4 |

| 2 | RADHA D N | 1KT23ME009 | 542/800 | 67.8 |

| Toppers list: 7th sem (21 scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total marks | Percentage |

| 1 | SANJAY V T | 1KT21ME005 | 574/700 | 82 |

| 2 | SURYA GAYATHRI | 1KT21ME006 | 569/700 | 81.3 |

| 3 | SHREECHARAN A | 1KT22ME401 | 531/700 | 75.9 |

| Academic Year - 2023-24 (Even Sem) | ||||

|---|---|---|---|---|

| 4th sem (22 Scheme) | ||||

| Sl.No | Name | USN | Total marks | Percentage |

| 1 | HARSHA G | 1KT23ME400 | 643/900 | 71.44 |

| 6th sem (21 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total marks | Percentage |

| 1 | SURYA GAYITHRI V | 1KT21ME006 | 649/800 | 81.13 |

| 2 | SANJAY V T | 1KT21ME005 | 612/800 | 76.50 |

| 3 | HEMANTH GOWDA H L | 1KT21ME003 | 598/800 | 74.75 |

| 8th sem (18 scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total marks | Percentage |

| 1 | ASHISH K S | 1KT21ME401 | 425/500 | 85.0 |

| 2 | HEMANTH A S | 1KT20ME002 | 419/500 | 83.8 |

| 3 | VISHWA P | 1KT21ME405 | 417/500 | 83.4 |

| Academic Year - 2023-24 (odd Sem) | ||||

|---|---|---|---|---|

| Toppers list: 5th Sem (21 Scheme) | ||||

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | SURYA GAYITHRI | 1KT21ME006 | 582/800 | 72.75 |

| 2. | HEMANTH GOWWDA H L | 1KT21ME003 | 536/800 | 67.00 |

| Academic Year - 2023-24 (Even Sem) | ||||

|---|---|---|---|---|

| Toppers list: 8th Sem (18 Scheme) | ||||

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | ASHISH | 1KT21ME401 | 425/500 | 85.0 |

| 2. | HEMANTH A S | 1KT20ME002 | 419/500 | 83.8 |

| 3. | VISHWA P | 1KT21ME405 | 417/500 | 83.4 |

| 4. | KEVIN STEEVAN DSOUZA | 1KT21ME402 | 397/500 | 79.4 |

| Academic Year - 2022-23 (odd Sem) | ||||

|---|---|---|---|---|

| Toppers list: 3rd Sem (21 Scheme) | ||||

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | SURYA GAYITHRI | 1KT21ME006 | 626/800 | 85.75 |

| Toppers list: 5th Sem (18 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | VISHWA P | 1KT21ME405 | 639/900 | 71.00 |

| 2. | HEMANTH A S | 1KT20ME002 | 615/900 | 615/900 |

| 3. | ASHISH K S | 1KT21ME401 | 587/900 | 65.22 |

| 4. | VISHWA P | 1KT21ME404 | 556/900 | 61.78 |

| Toppers list: 7th Sem (18 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | TANUJ KUMAR S | 1KT19ME009 | 645/800 | 80.63 |

| 2. | AMITH GOWDA | 1KT18ME002 | 610/800 | 76.25 |

| 3. | KARTHIK RAI | 1KT19ME004 | 597/800 | 74.63 |

| 4. | ANAYATHULLA/SAIPRAKASH | 1KT19ME005 /1KT19ME008 | 588/800 | 73.50 |

| Academic Year - 2022-23 (Even Sem) | ||||

|---|---|---|---|---|

| Toppers list: 6th Sem (18 Scheme) | ||||

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | HEMANTH A S | 1KT20ME002 | 579/800 | 72.37 |

| 2. | VISHWA P | 1KT21ME404 | 576/800 | 72.00 |

| 3. | VISHWA P | 1KT21ME405 | 567/800 | 70.88 |

| 4. | ASHISH K S | 1KT21ME401 | 550/800 | 68.75 |

| Toppers list: 8th Sem (18 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | THANUJ KUMAR | 1KT19ME009 | 445/500 | 89.0 |

| 2. | KARTIK RAI | 1KT19ME004 | 415/500 | 83.0 |

| 3. | SAIPRAKASH | 1KT19ME008 | 415/500 | 83.0 |

| 4. | MD ANAYATULLA | 1KT19ME005 | 406/500 | 81.2 |

| Academic Year 2021-22 (Odd Sem) | ||||

|---|---|---|---|---|

| Toppers list: 3rd Sem (18 Scheme) | ||||

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | HEMANTH A S | 1KT20ME002 | 675/900 | 75.00 |

| 2. | ASHISH | 1KT21ME401 | 675/900 | 75.00 |

| 3. | VISHWA P | 1KT21ME405 | 671/900 | 74.56 |

| 4. | FAIZ AHMAD KHAN | 1KT20ME001 | 604/900 | 67.22 |

| Toppers list: 5th Sem (18 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | THANUJ KUMAR S | 1KT19ME009 | 679/900 | 75.44 |

| 2. | MD. ANAYATHULLA | 1KT19ME005 | 619/900 | 68.78 |

| 3. | KARTHIK RAI | 1KT19ME004 | 573/900 | 63.67 |

| 4. | SAI PRAKASH H T | 1KT19ME008 | 562/900 | 62.44 |

| Toppers list: 7th Sem (18 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | SUMANTH MANJUNATH | 1KT18ME018 | 631/800 | 78.88 |

| 2. | HARSHITH GOWDA K G | 1KT18ME008 | 628/800 | 78.50 |

| 3. | KIRANSWAMY | 1KT18ME009 | 623/800 | 77.88 |

| 4. | SALMAN ANSARY | 1KT18ME017 | 622/800 | 77.75 |

| Academic Year - 2021-22 (Even Sem) | ||||

|---|---|---|---|---|

| Toppers list: 4th Sem (18 Scheme) | ||||

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | HEMANTH A S | 1KT20ME002 | 642/900 | 71.33 |

| 2. | VISHWA P | 1KT21ME404 | 570/900 | 63.33 |

| Toppers list: 6th Sem (18 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | THANUJ KUMAR S | 1KT19ME009 | 580/800 | 72.3 |

| 2. | MD. ANAYATHULLA | 1KT19ME005 | 575/800 | 71.89 |

| 3. | SAI PRAKASH H T | 1KT19ME008 | 550/800 | 68.75 |

| 4. | KARTHIK RAI | 1KT19ME004 | 523/800 | 65.4 |

| Toppers list: 8th Sem (18 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | PRAMOD | 1KT18ME014 | 447/500 | 89.4 |

| 2. | SUMANTH MANJUNATH | 1KT18ME018 | 439/500 | 87.8 |

| 3. | DHANUSH | 1KT17ME010 | 436/500 | 87.2 |

| 4. | NAGARAJU | 1KT18ME012 | 435/500 | 87.0 |

| Academic Year - (Odd Sem) | ||||

|---|---|---|---|---|

| Toppers list: 3rd Sem (18 Scheme) | ||||

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | Thanuj Kumar | 1KT19ME009 | 714/900 | 79.33 |

| 2. | Sai Prakash | 1KT19ME008 | 575/900 | 63.88 |

| Toppers list: 5th Sem (18 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | Sumanth Manjunath | 1KT18ME018 | 683/800 | 75.89 |

| 2. | Harshith Gowda | 1KT18ME008 | 682/800 | 75.78 |

| 3. | Kiran Swamy | 1KT18ME009 | 659/800 | 73.22 |

| 4. | Nagaraju H S | 1KT18ME012 | 636/800 | 70.67 |

| Toppers list: 7th Sem (17 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | Noornabi Hussain | 1KT17ME021 | 686/800 | 85.75 |

| 2. | Andrila Bose | 1KT17ME003 | 649/800 | 81.12 |

| 3. | Prajwal P Jigalore | 1KT17ME024 | 643/800 | 80.38 |

| 4. | Sandeep Kumar | 1KT17ME029 | 623/800 | 77.88 |

| Academic Year - (Even Sem) | ||||

|---|---|---|---|---|

| Toppers list: 4th Sem (18 Scheme) | ||||

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | Thanuj Kumar | 1KT19ME009 | 745/900 | 82.77 |

| 2. | Md. Anayathula | 1KT19ME005 | 630/900 | 70.00 |

| 3. | Kartik Rai | 1KT19ME004 | 615/900 | 68.33 |

| 4. | Sai Prakash | 1KT19ME008 | 593/900 | 65.89 |

| Toppers list: 6th Sem (18 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | Pramod S | 1KT18ME014 | 769/900 | 85.44 |

| 2. | Harshith gowda K G | 1KT18ME008 | 755/900 | 83.88 |

| 3. | Sumanth Manjunath | 1KT18ME018 | 753/900 | 83.66 |

| 4. | Ajay.J.Naik | 1KT19ME400 | 742/900 | 82.44 |

| Toppers list: 8th Sem (17 Scheme) | ||||

|---|---|---|---|---|

| Sl.No | Name | USN | Total Marks | Percentage |

| 1. | Noor Nabi Hussain | 1KT17ME021 | 703/800 | 87.88 |

| 2. | Shivendriya R | 1KT17ME032 | 648/800 | 81.00 |

| 3. | Parabin Kumar Mahato | 1KT17ME023 | 645/800 | 80.63 |

| 4. | Sandeep Yadav | 1KT17ME031 | 634/800 | 79.25 |